Urgent Call

Moving into the labyrinthine world of product compliance for safety testing for the BIS approval has a far bigger meaning; it is in fact the ticket to trust, credibility, and access to the Indian market.

Sunren takes you through this exhaustive process accurately and competently, always there to guide you.

The BIS stands to represent the national body in India that is responsible for ensuring that a product meets the minimal criteria stipulated for safety, quality, and performance.

The Bureau of Indian Standards (BIS) is the National Standards Body of India under the Department of Consumer Affairs, Ministry of Consumer Affairs, Food & Public Distribution, Government of India.

The organization was formerly the Indian Standards Institution (ISI), set up under the Resolution of the Department of Industries and Supplies No. 1 Std. (4)/45, dated 3 September 1946.

The BIS creates standards for almost everything artificially created for use by any entity. Accordingly, the BIS standardizes all devices/materials/products in electrical, electronic, mechanical, chemical, medical, metallurgical, and many other fields.

With effect from May 2013, the BIS introduced the CRS ( Compulsory registration scheme) for mandatory approval of a specific set of commonly used electronic and electrical devices, both imported and manufactured in India.

The CRS was aimed at guaranteeing the safety of the end user from the hazards of using poorly designed, electrically incompatible, and sub-standard build of cheaply imported equipment sold in the market

Accordingly, samples of the device/material/product prior to import have to be tested by a BIS-designated test facility for compliance with the relevant safety standard issued by the BIS.

Only BIS-approved devices/materials/products are allowed to be sold in the Indian market

BIS certification is synonymous with consumer confidence; basically, it is the BIS hallmark that works as proof of the quality of the product for the customers

Without which, your products might as well stand on some island, unrecognized, unsellable, and out of bounds.

These BIS standards include categories ranging from electrical appliances, IT, and telecom products to several others.

Safety testing ranges from electrical safety checks to mechanical durability tests and forms the rite of passage for your product to enter the Indian market.

Testing the heart and soul of your electronic devices means to ensure that they do not short-circuit, overheat, or turn into a fire hazard.

Voltage Surge Test: The test simulates spikes in power to make sure your product can handle erratic voltages.

Insulation Resistance Test: This is applied to guarantee that electric parts are appropriately insulated to avoid shock and malfunction.

This test puts the physical robustness of your product to test to see if it can, in fact, take everyday wear and tear.

Drop Test: This testing procedure ensures that the product is capable of taking a blow if it drops from a certain height.

Impact Resistance Test: Gives one a fair idea of how well your product can survive catastrophic impacts.

This can be like trying to thread a needle in a storm, but with proper guidance, it should be no problem at all. Here's how it goes.

01

Product and Documents Submission

Send in your product samples along with the related technical documentation-product schematics, lists of components, user manuals-you name it.

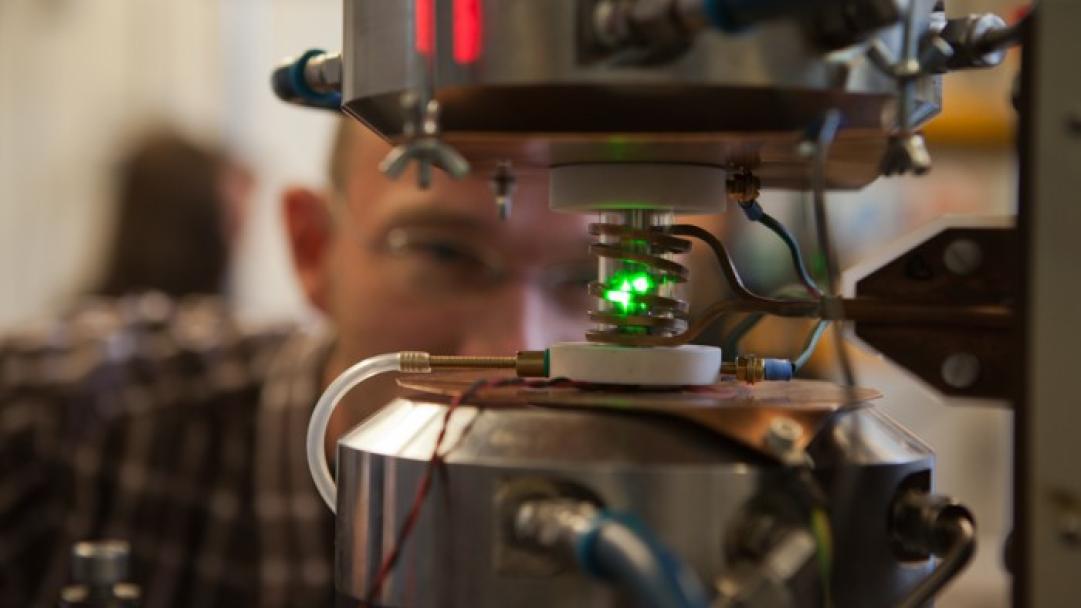

Testing at BIS-Recognized Laboratories

Once submitted, your product goes through all types of testing in labs accredited by BIS.

02

Safety testing is not a one-size-fits-all thing; each product has its unique test protocol, designed to simulate its function, usage environment, and potential hazards.

High-Temperature Exposure Test: Exposing your product to extreme heat to see whether it keeps its cool.

-Performing the thermal cycling test involves rapid changes from hot to cold with the intent of simulating real-life conditions.

Testing for EMC ensures your product does not interfere with, or get interfered by, other devices.

Radiated Emissions Test:

This tests whether your product's electromagnetic radiations are within permissible limits.

Conducted Immunity Test:

This test is performed to make sure your product is immune from external electromagnetic disturbances.

If your product passes testing, then the road to certification is easy. But if gets even better-think of it as the cherry on top of your compliance sundae.

With the certification from BIS in your hands, your product is now ready for the market.

With two decades of experience, state-of-the-art facilities, and a client-first approach, we can make safety testing for BIS approval feel less like an obstacle and more like a glide path to market success.

NABL-Accredited Laboratories: High-class facilities accreditation done both at national and international levels in.

Customized Testing Solutions: We do realize that each product has its uniqueness, and so do our ways of testing.

Let us get your products BIS-ready!

Contact Sunren today and let us make compliance your competitive advantage.